Trusted Lift Breakdown Assistance: Top Lift Servicing Companies Near You

Trusted Lift Breakdown Assistance: Top Lift Servicing Companies Near You

Blog Article

Professional Tips for Ensuring Security During Comprehensive Lift Repair Service Treatments

In the world of comprehensive lift repair service procedures, safety and security stands as a critical issue that necessitates meticulous focus to detail and adherence to developed methods. As the intricate interplay of machinery and human treatment unfolds, a critical technique to security comes to be the linchpin for effective repair work procedures.

Safety Equipment Requirements

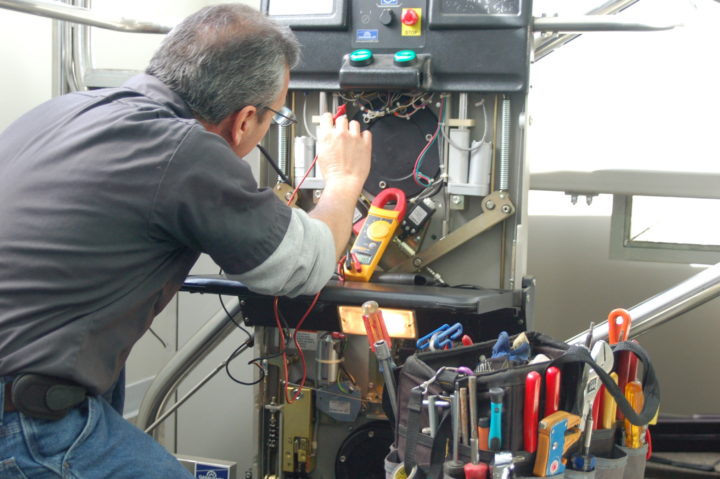

The security gear needs for lift repair service procedures are essential to ensure the wellness of maintenance workers. When functioning on lifts, upkeep personnel must adhere to strict safety protocols by using appropriate gear such as hard hats, safety goggles, gloves, steel-toed boots, and high-visibility vests.

Construction hats are important for protecting against head injuries from bumping or falling objects right into overhanging structures. Safety goggles safeguard the eyes from particles, chemicals, or triggers that might be created throughout repair. Handwear covers supply hand defense from cuts, burns, or electric shocks, while steel-toed boots provide foot protection from hefty things or tools. High-visibility vests make certain that upkeep workers are easily seen by others, reducing the threat of crashes because of poor visibility. By purely sticking to security gear needs, upkeep employees can reduce risks and job effectively to preserve and fix lifts.

Devices Examination List

To make certain the maintenance personnel's safety and security and the appropriate performance of lifts, a thorough tools examination checklist is important before commencing any type of repair service treatments. lift repair. This list ought to consist of a comprehensive evaluation of all components such as cable televisions, sheaves, electrical systems, and security systems. It is vital to check for any type of indications of wear and tear, corrosion, or damages that might compromise the lift's structural honesty or functional effectiveness

Along with mechanical components, the examination list must include safety and security attributes like emergency brakes, restriction buttons, and overload sensing units. These safety devices play an important role in guaranteeing and preventing crashes individual protection throughout lift operation.

Furthermore, validating the calibration of control systems, verifying appropriate air flow and lighting within the lift shaft, and looking for any blockages or particles are vital actions in the evaluation process. Regular maintenance and adherence to the devices inspection checklist not just boost security methods but likewise expand the lifespan of the lift system, minimizing the likelihood of expensive repair services or unexpected failures.

Threat Identification Methods

Making use of organized analysis techniques, danger recognition methods are utilized to pinpoint possible threats within lift repair service procedures. One usual method is the Task Security Analysis (JSA), where each step of the fixing procedure is very carefully evaluated to recognize possible risks and determine the best safety and security procedures to reduce them.

Emergency Response Readiness

With a concentrate on ensuring swift and efficient action to unanticipated scenarios, emergency situation feedback preparedness is an essential facet of keeping safety and security throughout lift fixing procedures. Prioritizing emergency situation preparedness entails developing clear communication channels, assigning specific duties and obligations, and performing routine drills to test action times and pop over to these guys procedures.

Key components of emergency feedback preparedness consist of having readily easily accessible emergency treatment kits, fire extinguishers, and emergency situation contact details prominently showed. It is crucial to train all workers entailed in lift repair work treatments on emergency action protocols, consisting of just how to safely leave the location in case of a fire or other emergency situations.

Moreover, creating a detailed emergency situation reaction strategy specific to lift repair service circumstances can help reduce possible risks and make sure a punctual and coordinated action in case of an incident. Frequently assessing and upgrading this strategy based on lessons gained from previous drills or you can try this out cases is vital to constantly enhance security procedures throughout lift repair procedures.

Ongoing Security Training

Regular education and learning and training in safety and security methods is a basic part of ensuring the ongoing safety of personnel during lift repair procedures. Ongoing safety and security training plays an important function in keeping workers informed about the most up to date security requirements, procedures, and ideal techniques in the industry (lift repair). By giving regular training sessions, workers can remain up-to-date on prospective threats, secure work treatments, and emergency procedures particular to lift repair service settings

Normal safety and security training also aids enhance the value of following safety standards and procedures whatsoever times. It instills a safety-conscious attitude among employees, promoting a culture of security within the work environment. Additionally, continuous training allows employees to freshen their understanding and abilities, improving their readiness to manage any unpredicted security obstacles that may emerge during lift fixing procedures.

To ensure the performance of ongoing security training, it is important to tailor the web content to the specific risks and demands related to lift repair procedures - lift breakdown. Employers need to regularly examine training needs, offer possibilities for hands-on practice, and motivate open interaction regarding security worries amongst all employees included in lift fixing operations

Final Thought

In verdict, ensuring security during extensive lift repair service treatments is necessary for avoiding injuries and mishaps. By adhering to safety and security gear requirements, conducting devices assessments, determining threats, getting ready for emergency situations, and giving recurring safety training, workers can minimize risks and create a safe workplace. Focusing on safety and security actions and remaining vigilant throughout the repair process will help shield both employees and the tools being serviced.

When working on lifts, maintenance workers need to Find Out More adhere to rigorous security protocols by wearing ideal equipment such as hard hats, safety goggles, handwear covers, steel-toed boots, and high-visibility vests. One usual strategy is the Task Security Analysis (JSA), where each action of the fixing procedure is meticulously evaluated to identify potential threats and figure out the finest safety actions to alleviate them.Regular education and training in safety procedures is a fundamental part of making sure the continuous safety and security of workers during lift fixing treatments.Regular safety and security training also assists reinforce the relevance of complying with safety standards and procedures at all times. By adhering to safety equipment requirements, performing equipment examinations, determining threats, preparing for emergencies, and giving continuous safety and security training, workers can decrease risks and produce a safe work atmosphere.

Report this page